ambition

in space.

Satellite Radiator:

Radiators are part of the Thermal Control System (TCS). Their role is to reject heat created on the spacecraft to the deep space. Radiators exist in several different forms, such as flat-plate radiators and structural panels mounted to the side of the satellite.

Our radiator development and production process includes:

- CAD design (SolidWorks),

- structural analysis (SolidWorks Simulation, NASTRAN),

- thermal analysis (NASTRAN, ESATAN),

- machining (laser cutting, sawing, turning, CNC milling),

- conversion coating (hexavalent chromium coating, trivalent chromium coating, passivation),

- thermo-optical coating (white painting, black painting, second surface mirror gluing),

- assembly (insert gluing, fastening, riveting, gluing, taping),

- verification (3D measurement, vibration testing, thermal testing),

- cleaning (bakeout, critical cleaning in ISO 8 cleanroom / ISO 5 clean bench).

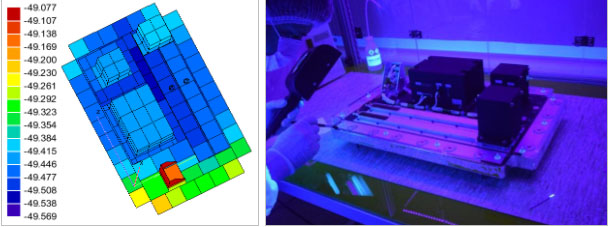

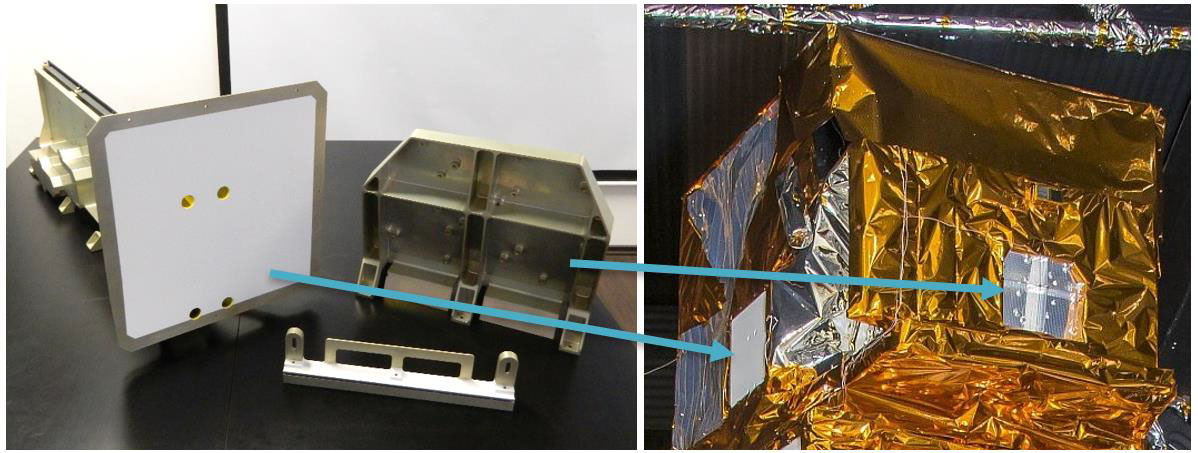

Admatis has more than 10 years of experience developing radiators for satellite payloads and platforms. The company delivered passive instrument- and harness radiators for the Sentinel-2A and 2B satellites launched in 2015 and 2017. Admatis was the subcontractor of ASTRIUM (now AIRBUS) responsible for development, manufacturing and structural testing. Several procedures have been space qualified during this project such as CAD design, structural and thermal analysis, machining, conversion coating, white painting, assembly, cleaning and vibration testing. Due to successful project implementation, Admatis was contracted by AIRBUS to deliver the third and fourth flight set of metallic mechanical and thermal hardware (MMTH) to be integrated to Sentinel-2C and 2D spacecraft between 2015 and 2017.

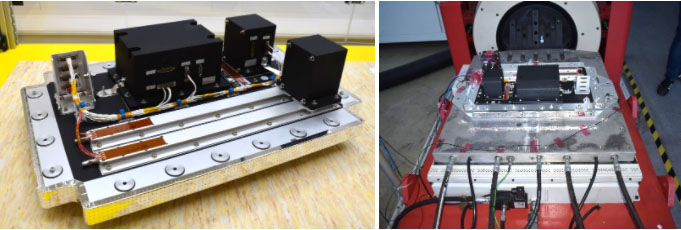

Admatis joined the CHEOPS industrial consortium led by the University of Bern in 2016. Our company delivered FPA and FEE radiators for the scientific instrument of the CHEOPS satellite launched in 2019. Admatis’ responsibility was the design, manufacturing and verification of radiators Structural Thermal Model (STM) and Flight Models (FM). Design activity included thermal and structural FE analysis to optimize mechanical and thermal properties. The raw material of radiators is aluminium alloy, baseline machining processes are CNC milling and turning. As a new element, SSM gluing technology was developed since the qualified white painting was not suitable as the thermo-optical coating due to the wide operational temperature range. All surface treatment activities including SSM bonding 2216 have been performed at Admatis’ premises.

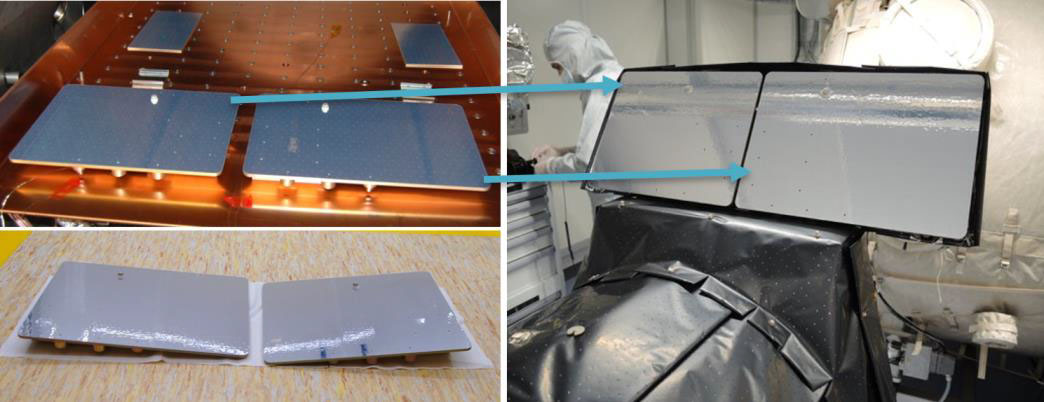

The satellite radiators developed for Sentinel-2 and CHEOPS are integrally milled types, which has limited heat rejection capacity due to its limited size. Admatis wanted to improve the heat rejection capacity of the radiator product line. The best candidate was the radiator made from sandwich panel which is extensively used as platform sidewalls. Our company also wanted to increase its competency regarding production of more complex thermal control subsystems. To do so, a development project has been started in 2017 funded by ESA targeting design, manufacture and verification of a complex platform radiator prototype consisting of:

- an aluminum honeycomb sandwich panel assembly,

- mass thermal dummies (MTD)

- doublers,

- thermal fillers,

- heat pipes,

- second surface mirror,

- thermo-optical black paint,

- flight and test heaters,

- flight thermistors

- and a test harness with micro-D connectors.

This complex hardware required developing a diverse set of manufacturing processes. Baseline machining process was CNC milling and turning. Metallic parts were conversion coated to ensure proper corrosion resistance. Inserts were embedded in the panel with low density potting compound using a pneumatic applicator gun. SSM and edge closure was bonded to the structure by PSA, while harness supports and MLI standoffs were bonded with paste adhesive. Conductive black paint was applied on the panel and MTDs using a manual applicator gun. Soldering and crimping processes were used to create interconnections between lead wires and electrical parts. At the successful thermal and vibration testing, developed technologies reached TRL6.

and we will answer you.